The Definitive Guide to Caster Manufacturer

Caster Manufacturer - The Facts

Table of ContentsGetting My Caster Manufacturer To WorkThe Facts About Caster Manufacturer UncoveredLittle Known Questions About Caster Manufacturer.Fascination About Caster ManufacturerThe 4-Minute Rule for Caster Manufacturer

Wheel wheels are utilized in buying carts, workplace chairs, clinical beds, and also material handling devices. Caster wheel variations differ greatly based on the application requirements as well as are extensively utilized in a variety of applications. It is a fantastic movement enabler, with buildings such as strength, deterioration resistance, water resistance, as well as weather resistance.

Heavy items need wheels with thicker wheels, some larger objects might need multiple wheels to uniformly disperse weight. This section will certainly talk about the production processes entailed in making wheel wheels.

Plasma cutting is a kind of thermal reducing that uses an ionized gas to cut the steel. This suggests that the procedure uses warmth to thaw the steel instead than mechanically sufficing. It is just one of one of the most typical approaches for reducing thick metal plates, but it's also valuable for sheet steel.

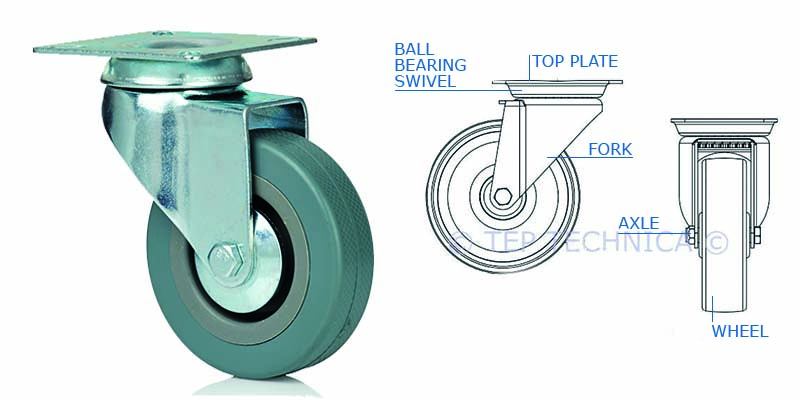

The next component to be cut is the fork. Forks are the arms that hold each side of the wheel axle. The forks are constructed of steel coil, a much more adaptable and also thinner sort of steel. The steel coil is turned out and fed into a strike press device which breaks it with the yoke shaped dye.

3 Simple Techniques For Caster Manufacturer

The press flexes the piece into the needed shape as well as it also makes a circular groove around the opening between. The hole is full of steel round bearings that enable the yoke to swivel - Caster Manufacturer. A steel retainer is fitted to hold the sphere bearings in place. The grooves of the steel cap are full of sphere bearings as well after that they put it onto a strike press and place the yoke on the top.

After captivating the leading plate to the yoke, put a steel seal over the retainer and also lock it in place with a pneumatically-driven press. The next machining procedure on the production of caster wheels is the extrusion of the wheel material. To make the wheels, nylon inserts are needed. The inserts are put in an injection molding press, which melt neoprene rubber and also injects it into the mold and mildew.

The rubber side absorbs shock, reduces sound, and protects against damage to the floor or surface. For bigger sized wheels, a different molding press is made use of to fit the called for size. The molding process to generate the wheel is the same. These bigger molding press machines usually make one wheel at once.

The steel guides place the wheel between the yokes and insert the steel wheel axle. A bolt head protects one end as well as a nut is affixed to the various other end. Oil is infused to lubricate the ball bearings. The wheel needs to undertake a collection of quality assurance tests that count the number of revolutions a caster can stand up to prior to it ultimately damages.

A Biased View of Caster Manufacturer

A swivel caster, on the other hand, may be a far better option if there's need for even more ability to move. Consider additionally whether there's requirement for swivel locks, if equipment is to be relocated a straight line - Caster Manufacturer. The capability to move something is why wheels are placed on it, however there's also require to know just how much liberty there remains in that motion.

Many applications call for a stem mounted wheel, although this can limit the wheel's weight capacity. Durable wheels will make use of a plate mount to safeguard the caster as well as disperse the lots over a greater installing area. Knowing the mounting choice can aid limit the alternatives when choosing wheels from a huge number.

This inquiry will certainly assist review if there's a need for light-duty, medium-duty, or heavy-duty wheels based on the total weight that will be put on them. Wheel wheels differ ranging with applications that are from clinical, industrial, furnishings wheels, and so on.

They are chemical, oil, and also acid immune due to the fact that they are made up of thermoplastic and also mold-on rubber. While a soft tread enables wheels to surrender small particles and is generally quieter than other products, it additionally makes it harder to roll as well as lowers the wheel's total lots ability. Polycarbonate rubber, rubber step on iron core, and also polyurethane step on plastic core are all usual soft tread caster wheels.

The smart Trick of Caster Manufacturer That Nobody is Discussing

They are additionally used in food service tools, handling plants, and also other light to medium loads. Ferrous wheels provide the greatest load capability, effect resistance, temperature level range, as well as rollability of any kind of caster wheel offered because of the solid structure it has. Ferrous wheels, as click this the name implies, are made from forged steel or cast iron, making it superb for severe situations such as stockrooms and also producing factories where flooring protection is not a top priority.

Solid urethane wheels are one approach to protect against these problems. The concern of tread splitting up and core rust is lessened due to the fact that the entire wheel is constructed from molded urethane with no core. Artificial wheels with a harder walk have a lower rolling resistance and also a greater influence stamina and integrity.

While a lot of artificial wheels are suitable for high-impact and rough circumstances, they are louder than softer products and also are much less forgiving when colliding with debris. Phenolic wheels, which are constructed from phenolic resin and also macerated canvas, are a constant choice for press pull applications. Phenolic wheels are solid and also stand up to grease and also other chemicals, making mobility less complicated.

Gray iron is made use of to make cast iron wheels. They're abrasion-resistant and also start this contact form rolling with little effort. These wheels are exceptionally resilient, designed for high-capacity applications, and can endure significant warm. This kind of caster wheel can operate concrete and also smooth steel surfaces. A few of the specifications discovered on this caster wheel consist of firmness of 90-95A; Brinell 145.

Get This Report about Caster Manufacturer

These wheels have a hardness of 130 150 brinell. Bearing made use of on these wheels may include: a plain bore, straight roller, as well as accuracy conical roller. Flanged wheel wheels can run within a temperature level of 800F given it has proper bearings and lubrication. This sort of caster wheel can operate in the following conditions: moderate chemicals, oily as well as greasy areas, as well as metal chips externally.

The strong wheels are solid in typical usage, can endure heats, and absorb shock as well as influence without failure. Forged steel wheels outshine ductile steel wheels in regards to tons ability, impact stamina, and also rollability of all caster wheels. Created steel caster wheels can be run on concrete and smooth steel surface areas.

Bearings that can be utilized include plain, tapered, Teflon, as well as roller bearings. These caster wheels can run under the exact same problems which are light chemicals, from this source oily and greasy areas, as well as steel chips on the surface area. These wheels are made up of a nylon and glass combination and are engineered to hold up against extreme temperatures.